PLM

PLM

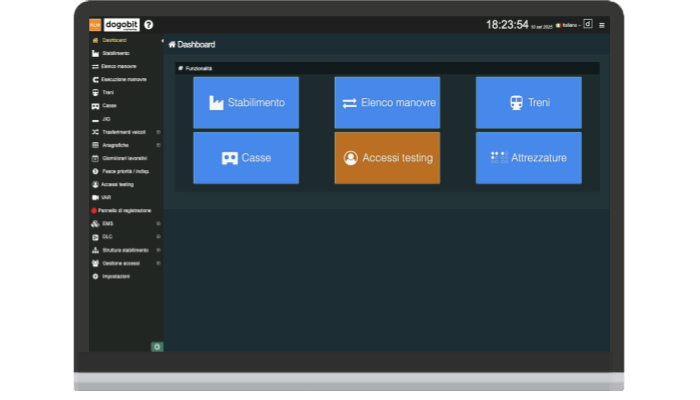

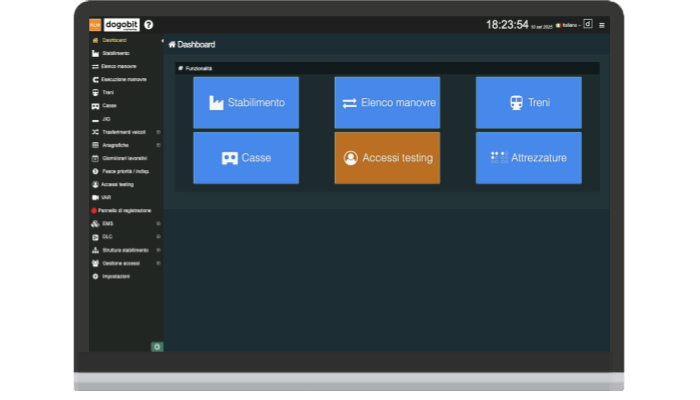

PLM, through a responsive web management console also suitable for use on mobile devices, allows the management of

resource movement and the planning and monitoring of movements made by the assigned personnel.

The main features of the system are the following:

The solution is customized from time to time to best adapt to the topography of each plant and allow real-time knowledge of the layout of the various monitored resources.

Thanks to this feature, the system is the ideal tool for monitoring the progress of the various processing phases and ensuring that they are carried out in compliance with the quality and safety criteria adopted within the company's production process.

Simple and intuitive interface. Web-based console that doesn't require installation on user PCs.

Adaptable to environments with multiple production plants.

System with multilingual interface.

Vector map of the facility with a list of all positions that can be occupied by resources, both for transit and stationary use, and the definition of movement constraints.

Each department can manage its own operations, leaving the system to check for any impediments to the execution of operations already scheduled for subsequent days.

Responsive web application with custom-developed sections for mobile use by operators who need to move around the facility.

Integrable with all existing third-party systems such as ERP, MES, access control systems, or any type of management software.

Module for managing access requests to areas requiring special authorizations, integrable with access control systems.

Module for managing video footage of vehicles leaving the plant to certify delivery conditions in the event of customer complaints.

Form for recording special equipment present at each workstation and monitoring its number against the requirements of the adopted production standards.

Module for defining new production line layouts to verify their efficiency in terms of units produced in a given time interval.

Ability to supplement application section data with various types of documents (including photos and videos), managing versioning, expiration, and role-based access to each document.

The high competence of Dogobit staff and their ability to grasp all the needs expressed by Hitachi, have created a strong synergy and collaboration within the working group, aspects that have allowed (even starting from scratch) the development and the creation of the CMS (Cars Monitoring System) in a relatively short time.

Read the entire contributionAre you interested in Plant Logistic Management?

Ask for a demo or further informations without any obligation.